Projects

Museum Victoria

Museum Victoria

Routine Maintenance

When JNJ Electrics won Museum Victoria’s (MV) Electrical Maintenance contract for Melbourne Museum in 2016, we also accepted the maintenance of the Royal Exhibition Buildings, Scienceworks & the Immigration Museum. JNJ immediately set up a transition process and performed an Electrical Audit on the each site to determine the condition and level of compliance of the extensive portfolio of assets.

JNJ worked closely with MV to set initial Priorities for testing and servicing the Air Circuit Breakers, Fuse Switches and Transfer Switches, including thermal scanning of each high current connection point. To minimise impact with the public, significant effort was put into scheduling works around the open hours across each of the facilities. Maintaining MV’s ESM compliance has also been a targeted priority and JNJ’s attention to detail and sophisticated documentation system ensured that MV always has access to current asset maintenance data.

Through working closely with the various Facilities and Project staff and from the extensive site knowledge gained by JNJ during the maintenance contract, MV now look to JNJ Electrics to provide recommendations and strategies to improve the lifespan, reliability and efficiency of their Electrical Installations.

Chadstone Shopping Centre

Chadstone Shopping Centre

Routine Maintenance

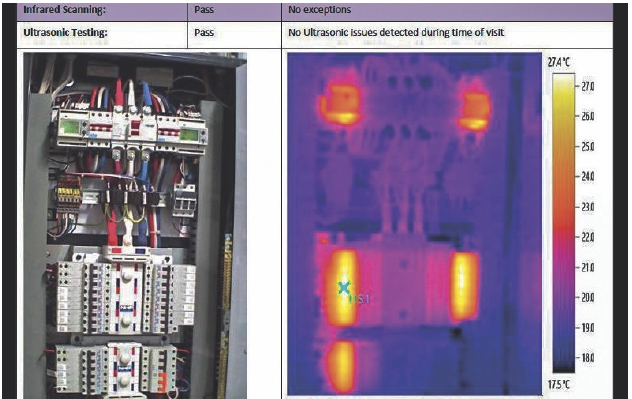

JNJ Electrics recently audited, analysed and carried out certified preventative maintenance for Vicinity Centres across the electrical low voltage distribution assets throughout the Chadstone Shopping Centre. Thermal scanning and ultrasonic testing was carried out to switchboards and other distribution assets, resulting in a 750 page audit and test summary report.

The report contained critical asset information, operational ratings and photographs of each asset, thermal images, future maintenance recommendations and a summary of identified issues, including priority ratings and references to the applicable Australian Standards for each identified defect.

The Building’s Operations Manager was notably impressed with JNJ’s quality of work, adherence to the Centre’s procedures and the high level of communication that was provided to schedule the works and co-ordinate access to each location.

St. Vincent’s Hospital Fire Rescue Victoria (FRV) Warringal Private Hospital

St. Vincent’s Hospital Fire Rescue Victoria (FRV) Warringal Private Hospital

Routine and Reactive Maintenance Contracts

Essential routine and reactive maintenance works have been core services delivered by JNJ to our clients for over 25 years.

The reliability and surety of the plumbing services we deliver are hallmarks that JNJ are widely known for.

Our Routine and Reactive Maintenance Contracts cover many vital areas of the licensed Plumbing trade, including:

• Preventative Maintenance Inspections

• Backflow Prevention and Thermostatic Mixing Valve testing

• 5 yearly Thermostatic Valve element replacement program

• Hot water system service, repair and replacement works

• Solar Hot Water systems

• Rainwater Harvesting systems

• Stormwater Drain inspection & repair works

• Roof and Gutter inspections and repairs

• Emergency Plumbing attendances and repairs

• Minor installation and upgrade works

• Standardizing fixtures & tapware

JNJ work closely with our clients to understand their priorities, systems & culture, all of which are crucially important factors for successfully delivering essential routine & reactive maintenance services within their dynamic work environments.

Our industry knowledge, reliability, value for money, and commitment to our client’s best interest ensures that JNJ Plumbing remains a preferred Contractor to proficiently and dependably deliver plumbing services to their critical facilities.

Dynon Freight Terminal

Dynon Freight Terminal

Capital Works

The level of yard lighting at this vital freight terminal was found to be well below the required standard, reducing both site safety and productivity around the yard. Providing a design solution to improve the lighting produced from these 35 metre high towers presented a number of challenges, particularly considering the large footprint and constantly busy nature of the site.

Coolon partnered with JNJ Electrics to provide a high efficiency maintenance free design solution using 36x 480w Industrial rated LED Flood Lights to replace the existing 48x 1000w HPS fittings. JNJ worked closely with Victrack to co-ordinate a suitable installation window and a strict timeline and works program was created to ensure the works rolled out according to plan. The JNJ team brought in a massive 55m boom lift to replace the fittings and a closely co-ordinated effort with the Coolon team ensured that the results accurately reflected the design. Once the commissioning phase had been completed, and measurements were taken across the site, it was confirmed that there was an average increase in light levels of over 400% and a reduction in annual operational costs of 82%. Both Victrack and the site tenant were amazed by the difference this lighting solution had provided to the site and greatly appreciated the results that both Coolon & JNJ Electrics was able to produce with minimal disruption to regular site activities.

Victorian Emergency Services Organisation

Victorian Emergency Services Organisation

Trade Waste Tank Cleaning & Inspection

The Craigieburn Emergency Services Training Centre uses a 30,000 litre below ground trade waste effluent tank, to recycle fire fighting water & associated foam products.

The task was to pump out, clean, and inspect this tank, which is a Confined Space, with the work being classified as High-Risk.

A detailed Safe Work Method Statement (SWMS) was created to identify risks & hazards, with suitable strategies adopted to ensure work could proceed safely. The safety measures included:

• air quality monitoring equipment to be used;

• breathing apparatus to be worn by anyone entering the tank;

• Standby Rescue personnel and equipment;

• retrieval tripod, winch, & full body harness;

• Isolation of the tank for the duration of the job;

• warning signage and work area delineation measures.

Once the tank had been pumped out and cleaned with a high pressure washer, the waste was removed from site and disposed of to EPA requirements, with a Certificate of Disposal issued.

An internal inspection was undertaken of all surfaces, seams and joints. Photos were taken throughout the inspection process.

The tanks integrity was assessed and determined as being in sound operable condition with no requirement for internal repair.

The Tank was returned to active service and a detailed condition report was issued to the Training Centre ‘s Facilities Manager who expressed their appreciation for our attention to detail and adherence to our documented safety processes.

Various Clients

Various Clients

Backflow Device Testing & Servicing

JNJ Plumbing undertakes annual testing and servicing of Backflow Prevention Devices to keep these valves in good working order so that they can continue to safeguard the public water supply and protect our valued client’s facilities . This important routine maintenance function is required to be performed by an Accredited Practitioner in accordance with AS3500.1992 and AS2845.3:1993 Standards.

JNJ’s Accredited Plumber tests Backflow Prevention devices by turning off the downstream shutoff valve and connecting a specialized Backflow testing kit to pressure test the valve’s operation. If the valve operates correctly, we immediately return supply to the site. If it doesn’t pass the required pressure test, we repair or replace the faulty valve, and retest the repaired Backflow prevention system to verify it’s compliant operation.

Once the testing work has been completed, JNJ’s Plumber provides a test report to our client and lodges it on-line with the relevant water authority. These measures ensure the site remains compliant to the mandatory testing and reporting provisions for Containment Backflow prevention devices.

As many of JNJ Plumbing’s clients operate busy Emergency Service facilities such as FRV, Hospitals, Ambulance Victoria, etc, our approach to these testing works is to schedule suitable times around our client’s requirements to ensure they can maintain an uninterrupted water supply to their critical services

IMAX Melbourne

IMAX Melbourne

Reactive & Emergency

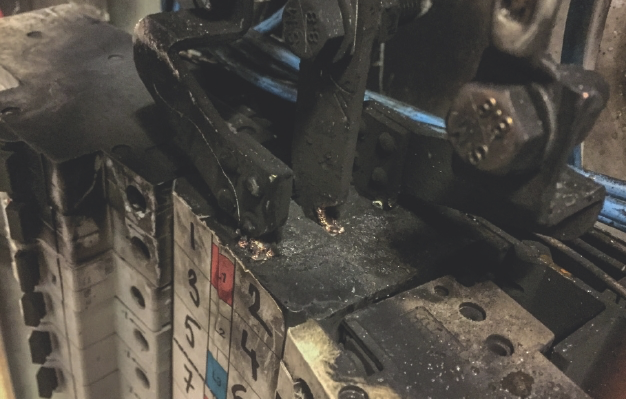

JNJ received an emergency call to IMAX Cinema at the Melbourne Museum. The Fire Brigade were on site and the building had been evacuated due to an electrical fire. The Children’s Area Café was also without power. The Museum needed all services restored quickly as it was a significant cost to have IMAX, its snack bars and the Childrens Area Café closed for an extended period of time.

After ensuring the site was made safe, the fire damaged switchboard was assessed for replacement by JNJ’s Electrician. A new switchboard was delivered overnight, and replaced at 6am the next morning. The switchboard and damaged cables were replaced and all affected services were restored in under 24 hours from when we were first notified of the fire.

An investigation into the cause of the fire revealed poor work practices by a Contractor on a recent installation project. The consequences could have been catastrophic, but fortunately the damage was contained within the switchboard. Even so, the costs incurred by the Museum in 24 hours of downtime were significant, however JNJ’s quick and effective response was commended by the Museum and minimised MV’s losses from the event.

Department of Defence

Department of Defence

Capital Works

JNJ won a contract to replace almost 60 switchboards within 30 Defence Bases across Victoria & Tasmania. Running parallel with this contract, JNJ successfully delivered another package of work across the same Bases & Depots to replace more than 7,500 Circuit Breakers with RCD’s (Safety Switches).

The logistical challenges surrounding the work included liaising with Building Managers and site personnel at each base, scheduling works to minimise disruption, arranging site access and security passes for each location, providing temporary generator supplies, isolating fire panels, identifying and safely removing equipment containing asbestos and ensuring that non-compliant situations were brought up to the relevant standards.

Numerous instances of non-compliant wiring were uncovered and investigated, with JNJ undertaking significant fault-finding and re-cabling works so that the newly installed RCD’s would function correctly. Comprehensive progress reports, electronic HOTO information and post-installation commissioning & documentation phases for each site were also significant project milestones that JNJ successfully and consistently delivered to the client’s complete satisfaction.

Historic Newport Railway Sheds

Historic Newport Railway Sheds

Reactive & Emergency

JNJ Electrics attended Newport Railway Heritage Workshops following an Arson attack that had gutted West Block Sheds 2 & 3 and badly damaged Shed 4. Fire Services had isolated power to the historic railway preservation precinct including the 11 historic Rail Sheds, Steamrail’s offices, the Administration Building and the Fire Museum’s workshop.

JNJ quickly assessed the situation, restoring power to eight of the sheds and providing generator supplies to other undamaged areas together with temporary power to the construction zones to enable demolition and asbestos removal works to get under way.

Once clearance to enter the burnt-out areas was issued, the JNJ team set about demolishing the existing electrical services & installing temporary hi-bay lighting and roller door supplies so that there-construction phase of the works could begin.

JNJ was also tasked with designing the electrical work for the reconstructed Heritage listed buildings. JNJ’s proposal included energy efficient LED Hi-bay lighting, emergency lighting and power distribution systems. The design complied with Australian standards, met Steamrail’s operational requirements and was visually sympathetic to the fabric of the historic sheds. Victrack approved JNJ’s design and re-construction works were completed on time and within budget.

Victrack & Steamrail representatives expressed their appreciation for JNJ’s pro-active approach, attention to detail and adaptability to meet the evolving requirements of the project, from the initial fault attendance through to the demolition, design, and installation phases of this important restoration work.

Various Clients

Various Clients

Zip Boilers and Chilled Water units

JNJ Plumbing supplies and installs Zip or Billi Boiling / Chilled water units for Hospitals, Fire Stations, Mess Rooms and Kitchenettes in all types of Commercial premises.

We recommend using select under bench units as they provide a safer delivery of boiling water than traditional above bench (wall mounted) units that are prone to an increased risk of splash scalding.

JNJ install these under bench Boiling & Chilled Water units at each location with bench mounted dispenser taps, to ensure safe, reliable and convenient operation.

Each unit’s installation is verified as being installed according to the manufacturers specified requirements.

We also maintain units on a 6 or 12 monthly basis, depending upon client requirements and manufacturer recommendations. Services can include replacement of water filters etc every 6 months according to usage and manufacturer guidelines.

JNJ Plumbing are specialists at working within busy Emergency Services Facilities, coordinating with each site to work around scheduled staff break times, or other periods of low activity, with a focus on minimizing any inconvenience to site operations.

Victorian Emergency Services Organisation

Victorian Emergency Services Organisation

Hot Water System, Reticulation & Flue

A project to upgrade the Craigieburn Emergency Services Training Centre’s unreliable hot water system was scheduled for the Christmas shutdown period, when the site was operating on a Holiday timetable. A 3 Stage Project Plan was created to coordinate our works with the Centre’s remaining daily activities to minimize any shut-downs.

Once the strict scheduling of works was finalized and agreed to with the Site Managers, JNJ’s Plumbers delivered the project according to the Project Plan, including maintaining the water supply to site services throughout the project’s three stages.

In Stage One, we replaced the Gas Hot Water Booster Units, which were changed over, tested & brought back on-line.

For Stage Two, JNJ’s Plumbers replaced the corroded hot water reticulation lines to all affected amenities in the Administration Building, primarily working within restrictive ceiling spaces.

The third stage was reserved for replacing the corroded complex flue system, and a specialist Flue Manufacturer was engaged to supply and install this combined flue under our supervision.

Once the combined flue had been tested, JNJ’s Plumbers conducted a comprehensive commissioning process to ensure the completed system was defect free and operating optimally.

With our completed installation, the site’s energy efficiency has been greatly improved with new 6 star rated Gas hot water units.

By replacing the aged and corroded reticulation lines and flue system, fault calls have been substantially reduced, which not only provides savings for the Centre’s Reactive Maintenance budget, but also considerably reduces the risk of unplanned outages at this very busy Emergency Services training facility.

Victorian Emergency Services Organisation

Victorian Emergency Services Organisation

Replacement of Fire Hydrant Service

JNJ’s on-call Plumber attended to a burst fire service at FRV’s Burnley Training Centre.Temporary repairs were quickly effected to ensure their fire system remained in service.

Upon investigation into the cause and extent of the issue, further evidence of corrosion was detected in various sections of pipework to the Training Tower.

A Condition Report detailing the extent of the problem was then prepared and issued to our clients, and a quotation was created to replace the damaged sections of pipework.

On acceptance of the quote, work plans were created to ensure a water supply and interim fire service were made available for the duration of the works.

A Fire Sprinkler Contractor was engaged to design & install the new system sections to the Training Tower, and the works were carefully scheduled to ensure the daily activities of the busy Training Centre were not disrupted.

Upon replacing the damaged pipework sections and fittings, we integrated them into the existing fire system, and reconnected it to the main water supply. The new pipework sections were also painted and labelled in accordance with ASS2419.1: 2005.

The recommissioned system was Pressure and flow tested, and the results and Project Completion Report were provided to FRV as part of the detailed As-Installed documentation dossier.

Ambulance Victoria & Fire Rescue Victoria

Ambulance Victoria & Fire Rescue Victoria

Safety Shower & Eye Wash Systems

Over several years, JNJ’s team of qualified Plumbers have installed Safety Showers & Eye Wash Stations at Fire Stations, Ambulance Victoria facilities, and Training Colleges to provide safer working conditions for Essential Service workers who may become exposed to hazardous or potentially toxic materials.

When installing these essential safety systems, we are always mindful of the fact that we are working around hazardous materials and within active, busy Emergency Services facilities. We coordinate our works closely with each site and carefully schedule any potentially disruptive activity, such as interrupting the water supply, to avoid disrupting normal site operations .

Each installed Safety Shower and Eye Wash Station has been tested and commissioned to the requirements of AS 4775:2007 and AS1319:1994 Standards , with the necessary completion report issued, and compliance tags installed.

We also perform annual testing of the Safety Showers and Eye Wash Stations to Contact JNJ AS4775:2007 and AS1319:1994 to ensure they are operable at all times. We install updated compliance tags and provide each site with a test report to verify the ongoing compliance of these important safety facilities

St Vincent’s Hospital

St Vincent’s Hospital

Replacement of Sanitary Drains

St. Vincent’s Hospital released minor project to replace the corroded sections of the sanitary drains within their carpark. This was the first stage of a major pipe replacement program. The Hospital areas located above the carpark had to be isolated for the duration of the removal & replacement of the drainpipes.

As a 24/7 hospital and carpark, careful work scheduling and effective communication were critical to the project’s success. Some work could only be undertaken during strict windows of availability, due to the main kitchen’s schedule, which finished late in the evening and started again early each morning.

Safety management within the 24/7 carpark required detailed coordination. Maintaining vehicular access was essential, whilst JNJ’s Plumber’s work area and equipment had to be segregated from both vehicular and pedestrian traffic.

Taking these factors into account, all works were performed after hours to minimize any potential disruption to hospital services and normal carpark access. After each night’s work, the main kitchen and other critical medical areas were back on-line by 6:00am each morning .

Disconnection and removal of the old pipework was carefully managed due to odours emitting from the disconnected drain.

Due to the site’s sensitivity, JNJ’s Plumbers controlled odours from the old pipework by plugging each opened section, removing them from site as soon as they had been detached.

The methodology, scheduling and control measures that JNJ’s Plumbing team employed were so successful that these same processes became the template for all subsequent work stages